The Sonic MEGA by Phrozen is an industrial-grade mono-LCD 3D printer that boasts a long-life monochrome LCD screen with ultra-high 8K definition, which makes it a professional machine that creates remarkably detailed models. Besides, it offers the largest printing area in the category for makers and product designers that are really passionate about bringing their most insane ideas to life. With the Sonic MEGA, you can now print big and have both size and quality in one print.

The MEGA 8K comes with a pre-calibrated build plate, dual linear rail and ball screw design, full metal exterior, and multi-fan cooling system to release excess heat from the device. This high-precision device is designed to be used in a variety of professional and industrial applications. Check out the following art models to assess the quality of 3D printing the device is capable of.

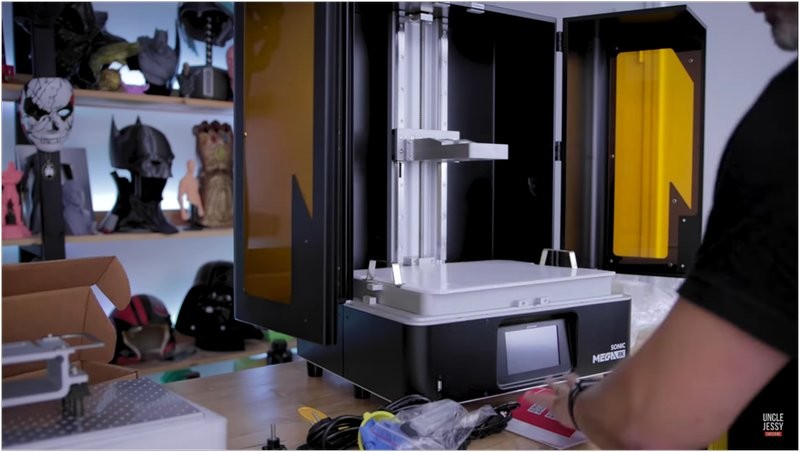

Here’s a sample print by Uncle Jessy:

Credit: @unclejessy4real / Instagram

Here’s a print of a Zombie Pumpkin completed by Lewis Villamar.

The machine apparently resembles the Phrozen Transform, the previous large-format product by the renowned Taiwanese company, but still has a number of differences, the major of which being the 8K resolution. Look through the following table to compare the two models in detail.

|

Model |

Phrozen Transform |

Phrozen Sonic MEGA 8K |

|

Material |

Aluminum |

Aluminum |

|

Print volume |

292 x 165 x 400 mm |

330 x 185 x 400 mm |

|

Print screen |

13.3" 4K RGB LCD 13.3" 4K monochrome LCD (optional) dual 5.5" 2K LCD (optional) |

15" 8K monochrome LCD |

|

XY resolution |

76 µm (standard panel) 47 µm (dual panel) |

43 µm |

|

Min. layer height |

10 µm |

10 µm |

|

Max. print speed |

10 mm/h (standard screen) 40 mm/h (mono screen) |

70 mm/h |

|

Control display |

5" color touchscreen |

5" color touchscreen |

|

Cooling system |

Multi-fan |

Multi-fan |

|

Connectivity |

USB, Ethernet, Wi-Fi |

USB, Ethernet |

The new Phrozen Sonic Mega is one of its kind with no alternative currently available on the market.

The Phrozen Sonic MEGA is a large-format LCD 3D printer that can print layers at a minimum layer thickness of 10 microns, with an XY positioning accuracy of 43 µm. This way, you can produce objects with extremely smooth exterior surfaces and striking details.

Check out this print:

Credit: @jankdprops / Instagram

The powerful 15-inch 8K monochrome LCD screen is the first of its kind for resin 3D printers, in terms of both size and resolution. This makes for the unprecedented print quality of outputs produced with the device.

More creative examples are presented in the pictures below:

Credit: @vered.rose.3d / Instagram

Credit: @batcave3dprint / Instagram

Credit: @lewis86_painting / Instagram

Credit: @zackariah_sekkat / Instagram

The Sonic MEGA 8K offers a variety of materials to choose from. It is compatible with both self-developed and 3rd party resins of 405 nm.

Credit: Maker’s Muse / YouTube

The Phrozen resin profile database includes ready-made profiles for 20+ different resins, including ABS-like Resin, TR250 High Temp Resin, Nylon-Green Tough Resin and a variety of Castable Resins.

Due to the built-in Phrozen Pump & Fill Automated Resin Feeder, the Mega 8K V2 ensures your resin vat is always properly filled, eliminating manual refills and resin shortage halfway through a large print job.

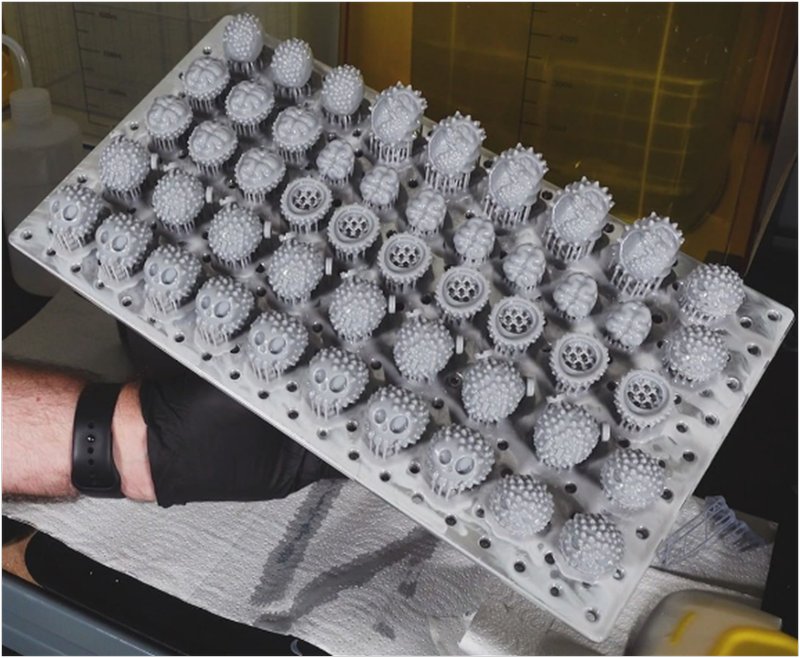

The Sonic MEGA 8K offers a spacious printing volume of 330 x 185 x 400 mm (12.9 x 7.3 x 15.7 in). With a 40 cm tall yet ultra-stable Z-axis, you can reliably print significantly larger models in one sitting. In addition, the model can comfortably fit multiple smaller parts in one batch, which will be especially great for mass production.

Credit: @lycheeslicer / Instagram

Now you can launch new products in no time!

The Sonic MEGA 8K can be controlled via PC or its built-in LCD touchscreen display and features Ethernet, USB, and SD card connectivity, which makes it a really accessible device.

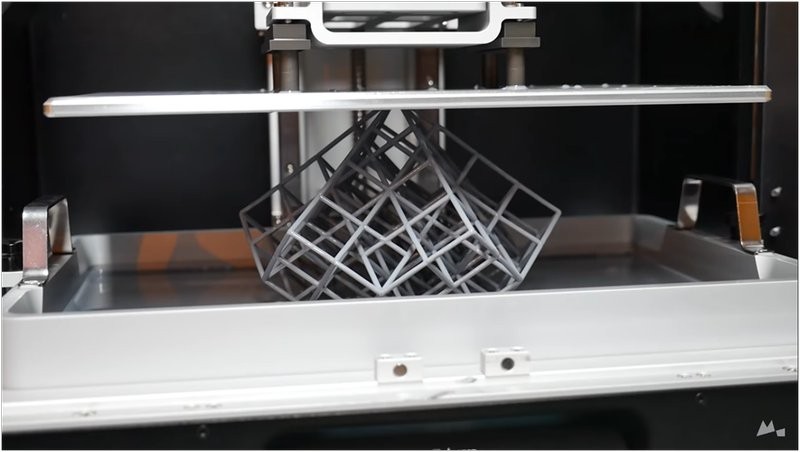

Credit: Uncle Jessy / YouTube

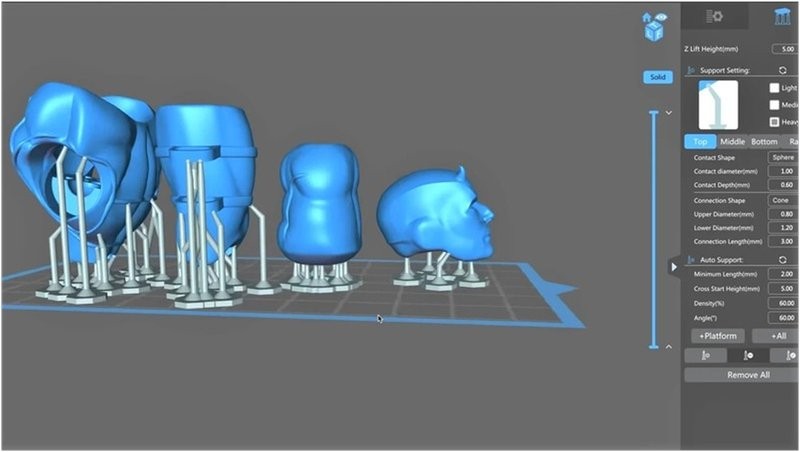

The printer can interact with a 3D model of almost any format and is compatible with ChiTuBox — a slicer optimized to work with SLA/DLP/LCD 3D printers.

Top 3D Shop provides dedicated tutorials on how to successfully run Chitubox with your Sonic Mega 8K 3D printer as well as the settings you need to use for your Phrozen resins.

Credit: Uncle Jessy / YouTube

For some items, the product’s package content may change. In case of any questions, please get in touch.

The Sonic MEGA 8K is available in black with dark-yellow transparent areas in the doors providing easy access to prints. Its stylish design makes it ideal for a number of professional and personal applications. The printer size is 40 х 47 х 68 сm (15.7 x 18.5 x 26.7 inches) and it weighs 35 kg (77 lbs). With the exterior completely made out of metal, the Sonic Mega 8K is a strong, heavy-duty device, its structure ensures sustainable operation over the long-term.

The dual linear rail ball screw design is used to minimize wobbling. As the 40cm tall Z-axis remains ultra-stable, the quality and precision of large prints is significantly improved.

The new 15" mono LCD screen guarantees long term usage and lasts twice as long as the RGB market alternatives (usually 2,000+ hours).

The Sonic MEGA 8K goes for $3,199.99, which is reasonable considering this product’s resolution, build area (one of the largest), and overall capabilities especially taking into account that no alternative is currently available on the market for this new device. By showcasing striking details at 43µm, the Sonic MEGA produces 3D models that are almost twice as detailed as other large-scale 3D printers.

Update your browser to view this website correctly. Update my browser now